Know the significance of dimensional control for on-site monitoring of building projects. With Shillong Design’s help, optimise measurements in construction.

When erecting a skyscraper or assembling intricate machinery, every measurement and dimension must be meticulously checked and verified through dimensional control. Dimensional control provides a comprehensive solution for on-site monitoring to ensure accuracy and adherence to specifications.

The Precision of Dimensional Control

Dimensional control is a systematic process used to verify and validate the accuracy of measurements and dimensions during all stages of a construction or engineering project. It involves the use of advanced surveying techniques, equipment, and software to monitor and analyse dimensional data, ensuring that components and structures meet design specifications.

One important thing about dimensional control is it helps maintain quality assurance throughout the project cycle. By making sure that measurements and dimensions are accurate and consistent, dimensional control helps identify and rectify deviations from design specifications early on, preventing costly rework and delays later in the project.

Adhering to precise dimensional requirements is also vital for compliance with building codes, safety regulations, and industry standards. Dimensional control helps structures and components meet these requirements, reducing the risk of safety hazards and regulatory non-compliance.

Precise dimensional control can also improve the performance and functionality of structures and equipment. By verifying dimensional accuracy, engineers can fine-tune designs to maximise efficiency, durability, and longevity, enhancing the overall performance and functionality of the finished product.

Shillong Design’s Dimensional Control

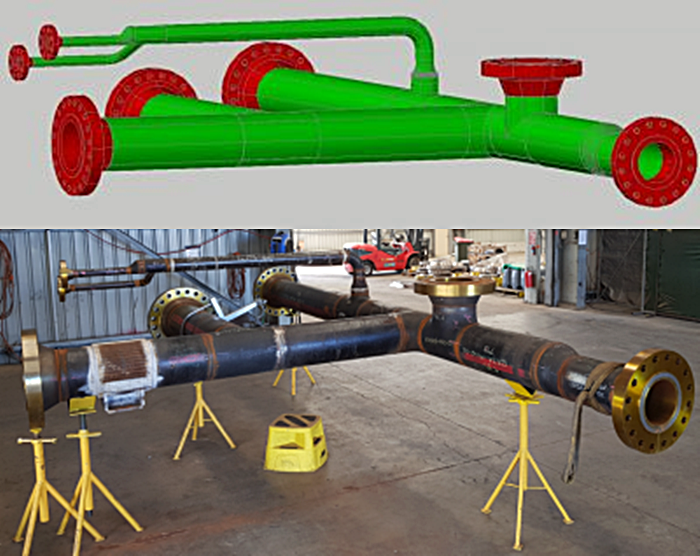

Shillong Design is a leading provider and pioneer of dimensional control surveying and laser scan surveys in Australia. Our team can leverage on 3D laser scanning to carry out dimensional control surveying, helping us capture detailed measurements of complex structures and components. Our laser scanners can generate highly accurate point clouds, which can be analysed to assess dimensional deviations and identify areas requiring adjustment.

Dimensional control can also be conducted through total station surveying. This type of surveying involves using electronic theodolites equipped with distance measurement capabilities to measure angles and distances with high precision. Total stations are often used for layout, alignment, and verification tasks in dimensional control.

Dimensional Control: Notable Benefits

When you opt for our dimensional control surveying, you can attain the following benefits for on-site monitoring of your construction project.

• Early Detection of Issues: Dimensional control allows for the early detection of dimensional deviations and discrepancies, enabling corrective action to be taken before they escalate into larger problems. This proactive approach helps prevent costly rework and delays downstream.

• Improved Communication: Dimensional control facilitates clear communication between project stakeholders. By providing accurate dimensional data in a format that is easy to understand, dimensional control helps ensure alignment and consensus among all parties involved.

• Data-Driven Decision Making: Dimensional control provides valuable data that can be used to inform decision-making throughout the project lifecycle. By analysing dimensional data, project managers can identify trends, anticipate potential issues, and optimise project outcomes.

Dimensional control by Shillong Design can ensure that measurements and dimensions of construction and engineering projects are accurate and consistent to meet design specifications. By hiring us, dimensional control enables you to mitigate risks, reduce costs, and contribute to the successful delivery of your project that meets or exceeds your expectations.