Explore how Shillong Design’s laser scanning enhances structural analysis and asset management. Optimise your project’s efficiency. Call us at 0414336672.

The landscape of technology evolves continuously as time passes. One of the innovations that has emerged as a game-changer for industries reliant on accurate data capture and analysis is laser scanning. From architecture and engineering to manufacturing and asset management, laser scanning has revolutionised the way structural analysis and asset information are gathered and utilised.

At Shillong Design, we ensure laser scanning will become an effective force in reshaping and honing structural analysis and asset management.

An Overview of the Laser Scanning Process

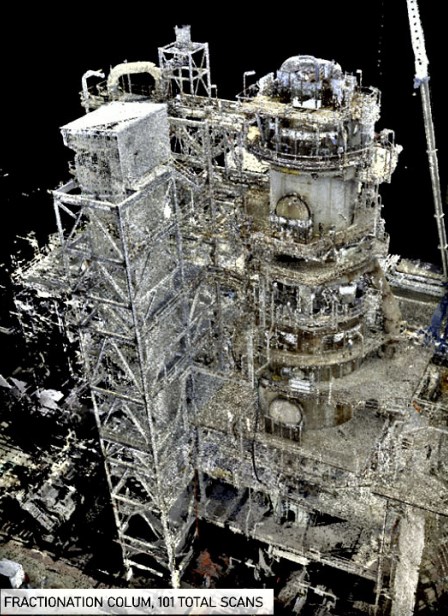

Laser scanning, also known as 3D laser scanning or lidar scanning, is a non-contact surveying method that takes advantage of laser light to capture precise and detailed 3D representations of objects, structures, and environments. The laser scanner emits a laser beam, which measures the time it takes for the laser to bounce back after hitting a surface. By combining these distance measurements with angular information, the scanner creates a point cloud or a collection of millions of individual data points representing the scanned object in three dimensions.

Shillong Design uses a combination of high-definition laser scanners and traditional survey instruments and principals to generate and deliver accurate and precise fit-for-purpose 3D spatial information. Through the gathered data, we can provide users with unfiltered, precise spatial information on existing site conditions, which helps make decisions based on the site context while minimising the need to visit the site.

Structural Analysis and Asset Management

Laser scanning can be utilised for various processes required for structural analysis. These processes include the following.

• Accurate 3D Data Capture: Laser scanning allows engineers and architects to obtain highly accurate 3D data of existing structures. This data can be used for modelling and analysing buildings, bridges, and other infrastructure with unprecedented precision.

• Inspection and Assessment: Traditional methods of structural analysis and inspection often involve manual measurements and visual assessments, which can be time-consuming and prone to human error. Laser scanning streamlines the process, which then enables faster and more accurate inspections.

• Real-Time Monitoring: Laser scanners can be used for real-time monitoring of structural movements and deformations, helping engineers identify potential issues and take proactive measures to maintain safety and stability.

Various aspects of asset management can also be done through laser scanning.

• Facility Management: In industries like manufacturing and warehousing, laser scanning allows businesses to create detailed as-built models of their facilities, helping them optimise layouts and plan future expansions.

• Maintenance Planning: Laser scanning can also give valuable data for asset management and maintenance planning. By creating digital twins of equipment and assets, businesses can monitor their condition, track wear and tear, and schedule maintenance proactively.

• System Efficiency: Laser scanning can identify inefficiencies in building systems and equipment, allowing businesses to implement energy-saving measures.

• Historical Preservation: In historical preservation projects, laser scanning can capture accurate 3D models of cultural heritage sites and artifacts. This data is invaluable for restoration efforts and documentation.

Laser scanning has emerged as a powerful tool for structural analysis and asset management across various industries, making it a valuable asset for businesses seeking to enhance efficiency, safety, and productivity. We, at Shillong Design, believe that laser scanning will play an increasingly significant role in reshaping the way we analyse structures and manage assets.