Elevate fabrication precision in Australia through dimensional control by Shillong Design. Explore how it secures integrity in manufacturing. Call 0414336672.

The integrity of fabrication processes in Australia can be enhanced by focusing on precision. At the heart of this need for precision lies dimensional control. It is a meticulous approach that measures and verifies key dimensions throughout the manufacturing cycle of a fabrication project.

Components of Dimensional Control

Dimensional control involves the accurate measurement, verification, and control of critical dimensions in manufactured components. These dimensions span lengths, widths, depths, diameters, and other geometric parameters crucial to a product’s functionality.

The primary objective of dimensional control is to guarantee that each component adheres to exact specifications, aligns with design requirements, and conforms to the intended geometry. We, at Shillong Design, make sure that the following components of dimensional control will be present, especially in a variety of fabrication projects.

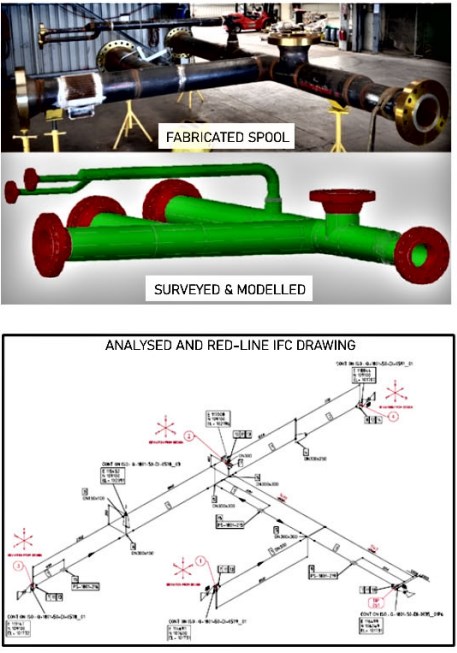

- Precise Measurement: At the core of dimensional control are precise measurement techniques. We employ advanced tools such as laser scanners and optical measuring devices to obtain accurate measurements and verify component dimensions against design specifications.

- In-Process Monitoring: Dimensional control involves continuous in-process monitoring. Real-time measurements at various stages of manufacturing enable the detection of deviations early on. This proactive approach allows for prompt corrections, which prevents the accumulation of errors and maintains dimensional accuracy throughout the fabrication process.

- Tolerance Verification: An integral aspect of dimensional control is the verification of tolerances. Our team at Shillong Design ensures that components adhere to specified tolerances so they can prevent issues related to fit, function, and overall product performance. Tolerance verification leaves no room for compromise when it comes to meeting design requirements.

- Feedback Loop: A robust dimensional control system establishes a feedback loop for continuous improvement. The data collected during dimensional control activities offer valuable insights into manufacturing processes. Manufacturers can utilise this information to refine processes, enhance tooling and fixtures, and implement corrective actions for ongoing improvement.

Dimensional Control and Fabrication

Dimensional control can influence fabrication integrity in a lot of ways.

By meticulously verifying component dimensions, manufacturers like you can ensure that each piece meets the required standards. This commitment to quality extends from individual components to the overall integrity of the final product.

Dimensional control can also contribute to consistency across production batches. Maintaining tight control over dimensions enables manufacturers to replicate precise components consistently, making this process vital to industries where interchangeable parts and standardised components are essential. The early detection of dimensional deviations through dimensional control can even mitigate the risk of error accumulation. Addressing deviations promptly prevents compounding issues that could lead to scrapped parts, rework, or compromised product integrity.

Lastly, components with accurate dimensions, verified through dimensional control, contribute to optimised fit and function in the final assembly, which can be useful in aerospace, automotive, and healthcare as they require end products that prioritise safety and performance.

Collaborating with Shillong Design

By letting Shillong Design carry out dimensional control for your fabrication, you not only uphold the highest standards of precision but also mitigate the risk of errors, enhance consistency, and optimise the fit and function of components. Dimensional control in modern manufacturing remains a fundamental aspect that safeguards fabrication integrity and the success of manufacturing operations.